- DIGITAL PROCESS INDICATOR

- API- 421

A digital process indicator is an electronic device that displays process variables like temperature, pressure, or flow rate numerically on a screen, often in industrial settings. These indicators receive input signals from sensors, commonly using a 4-20mA current loop or other analog inputs, and provide a clear, real-time reading of the process parameter. They are used for continuous monitoring in manufacturing, automation, and control systems. The term "SPECIAL PROCESS INDICATOR API 421" can refer to one of two distinct concepts, depending on the context, which can be easily confused:

- A specific model of digital process indicator: The API 421 is a model number for a physical panel-mount digital process indicator manufactured by various companies (e.g., ABM, Ztek Control Systems) in India and other regions.

- A "Special Process Indicator" field within a software system like SAP: This is a field or code used in Enterprise Resource Planning (ERP) systems (specifically SAP) that triggers special processing or calculation rules, with "API 421" possibly being a specific value or code used within that system, although this is less common than the general use of the term "Special Processing Indicator" in SAP contexts.

- Type: Panel-mount digital process indicator.

- Function: Measures and displays parameters like temperature, pressure, flow, voltage, or current from various sensors.

- Features:

- Display: Typically a 4-digit LED/LCD display.

- Inputs: Accepts standard industrial signals such as 4-20 mA, 0-10 V, thermocouples, and RTDs.

- Power Supply: Usually operates on standard AC power (e.g., 230 V AC).

- Mounting: Designed for easy integration into control panels.

- Applications: Used across various industries for real-time process monitoring.

- Function: Activates non-standard logic for tasks like shipping cost calculation, pricing, or accounting treatment (e.g., special G/L transactions).

- Usage: It is a configuration element within the SAP system rather than a physical device.

Key features and functions

- Digital display: Provides a numerical readout on an LED or LCD screen, making it easier to interpret than traditional analog meters.

- Universal input: Many models can accept a variety of input signals, such as 4-20mA, 0-10VDC, or thermocouple and RTD inputs, for flexibility across different applications.

- Process monitoring: Measures and displays real-time values for variables such as flow rate, temperature, pressure, level, pH, and more.

A digital process indicator is an electronic device used in industrial automation to measure, monitor, and display real-time values of critical process variables such as temperature, pressure, flow rate, level, voltage, and current.

Key Functions and Features- Real-time Monitoring: Provides an accurate, reliable, and immediate digital readout of process variables on an LED or LCD screen, which is often large for easy visibility in industrial environments.

- Input Compatibility: Designed to accept a wide array of input signals from various sensors and transmitters, including analog current (4-20 mA, 0-20 mA), analog voltage (0-10 V, 0-5 V), thermocouples (J, K, T, R, S types), and RTDs (Pt100).

- Programmability: Features a user-friendly interface with buttons for on-site programming and configuration, allowing users to set specific measurement units, scaling, offset, and alarm thresholds.

- Alarm Functions: Many models include programmable high and low limit settings with relay or buzzer outputs to notify operators of unusual process conditions, helping to prevent downtime and ensure safety.

- Communication Interfaces: Often equipped with communication options like RS485 Modbus, which enables integration with other control systems such as PLCs (Programmable Logic Controllers) or SCADA (Supervisory Control and Data Acquisition) systems for remote monitoring and control.

- Data Logging: Some advanced models offer data logging capabilities for storing and analyzing process data over time.

- Durable Construction: Typically housed in rugged, dust-proof or flame-proof enclosures (e.g., IP65 front rating) suitable for harsh industrial environments.

ApplicationsDigital process indicators are widely used across various industries, including:- Manufacturing: Monitoring temperature, pressure, and flow rates for quality control.

- Chemical and Petrochemical: Ensuring safe and efficient processes by monitoring pH, fluid levels, temperature, and pressure.

- Food and Beverage: Controlling temperature and ingredient proportions for consistency.

- Water Treatment: Tracking water flow and chemical levels to ensure compliance with quality standards.

- Power Plants: Displaying voltage, current, and power output for efficient operations.

SUPPLIERS:–

The reliable manufacturers and suppliers of based in India.

Customers from all across India are placing repeated orders, as there is no alternative available in terms of quality and performance.

Premium quality raw materials are used in the manufacturing that ensures noteworthy features such as high durability and resistance to abrasion.

How to contact us

If you’ve got questions or ideas you would like to share, send a message. For anything more specific, please use one of the addresses listed below.

Our Location :

Westside Controls 7.B.Murli Vihar Behind Canara Bank Sarojini Nagar Lucknow 226008

Factory Westside Controls

Khasra no-174, Amausi Station Road Naderganj Industrial Area Lucknow226008

Direct Line Numbers

9776806777 , 0522-3642558

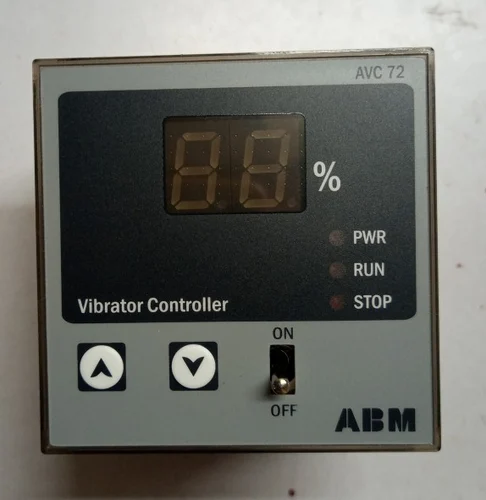

![VIBRATION CONTROLLER - [ABM]](https://factoryinputs.in/wp-content/uploads/2025/11/product-jpeg-500x500-3-430x430.webp)

![LIQUID LEVEL CONTROLLER - [ABM]](https://factoryinputs.in/wp-content/uploads/2025/11/product-jpeg-500x500-4-426x430.webp)

Reviews

There are no reviews yet.