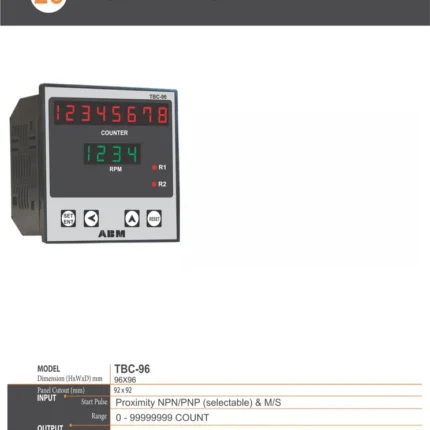

- SQT -96 (8 CHANNEL)

ABM - INSTRUMENT

ABM - INSTRUMENT

The query SQT 96 refers to a model of sequential timer, most commonly associated with industrial control applications. The "96" in the model name indicates the size of the device, which is 96 x 96 mm for panel mounting.

Sequential timers are used to operate multiple outputs in a timed sequence and are frequently seen in applications like dust collector systems and other industrial process controls.

Key specifications

The specifications can vary by the exact model. However, many of the SQT 96 models share these common features:

- Mounting: Panel mounted.

- Voltage: Many models operate on 100–270V AC supply.

- Display: Many models feature a digital LED display.

- Channels: The number of controlled outputs varies. Common options include 4, 8, or 12 channels.

- Outputs: Relay outputs are standard on these devices.

- Timing: The timing for each channel is programmable, with selectable units like seconds, minutes, or hours.

- Features: Some models include features like cascading capabilities, which allow multiple timers to operate together in sequenceThe SQT 96 sequential timer is a programmable, multi-channel control device used in industrial automation to activate a series of outputs (typically relays) in a specific, timed sequence. Its working revolves around precise, user-defined timing for each output channel.Core Working PrincipleThe SQT 96 operates based on a few key steps:

- Programming: The user sets parameters via the front keypad and dual LED display. These parameters typically include:

- The desired time range (seconds, minutes, or hours).

- The "On time" and potentially "Off time" for each individual channel.

- The operating mode (e.g., Delayed On, Delayed Off, or Cyclic).

- The number of cycles or channels to be used.

- Triggering: The sequence is initiated either by powering on the device, a dedicated start pulse from an external source (like a micro switch or proximity sensor), or a front panel key press.

- Sequential Activation: Once triggered, the microcontroller within the SQT 96 begins the timed sequence. It activates the first output channel for the user-programmed duration. After that time expires, it moves to the next channel, and so on, in a sequential manner.

- Output Control: Each channel typically has a relay output, which switches on or off external industrial devices (e.g., solenoid valves, lamps, motors) according to the programmed sequence. The front panel usually has indicator LEDs for each relay to show its current status.

- Cyclic or Single Run: The sequence can be set to run once (single mode) or repeat continuously (cyclic mode).

- Memory Retention: The SQT 96 uses non-volatile memory to retain the programmed settings even after a power failure, ensuring seamless operation when power is restored.

Common ApplicationsA primary application for the SQT 96 timer is in bag house (dust collector) systems. In these systems, the timer controls the sequential injection of compressed air into filter bags (via solenoid valves) to clean them automatically, ensuring continuous operation of the system.It is also used in other industrial settings that require a series of events to happen in a specific, timed order, such as:- Conveyor systems

- Packaging machines

- Complex manufacturing processes

Advanced Features- Cascading: Some models (like the SQT-1044 or SQT-9611) have a cascading feature, allowing multiple timers to be linked together to control a higher number of channels (e.g., combining two 8-channel units to create a 16-channel system).

- Modes: Different operating modes (Delayed On, Delayed Off, Cyclic) offer flexibility for various application needs

- Programming: The user sets parameters via the front keypad and dual LED display. These parameters typically include:

SUPPLIERS:–

The reliable manufacturers and suppliers of based in India.

Customers from all across India are placing repeated orders, as there is no alternative available in terms of quality and performance.

Premium quality raw materials are used in the manufacturing that ensures noteworthy features such as high durability and resistance to abrasion.

How to contact us

If you’ve got questions or ideas you would like to share, send a message. For anything more specific, please use one of the addresses listed below.

Our Location :

Westside Controls 7.B.Murli Vihar Behind Canara Bank Sarojini Nagar Lucknow 226008

Factory Westside Controls

Khasra no-174, Amausi Station Road Naderganj Industrial Area Lucknow226008

Direct Line Numbers

9776806777 , 0522-3642558

![VIBRATION CONTROLLER - [ABM]](https://factoryinputs.in/wp-content/uploads/2025/11/product-jpeg-500x500-3-430x430.webp)

Reviews

There are no reviews yet.