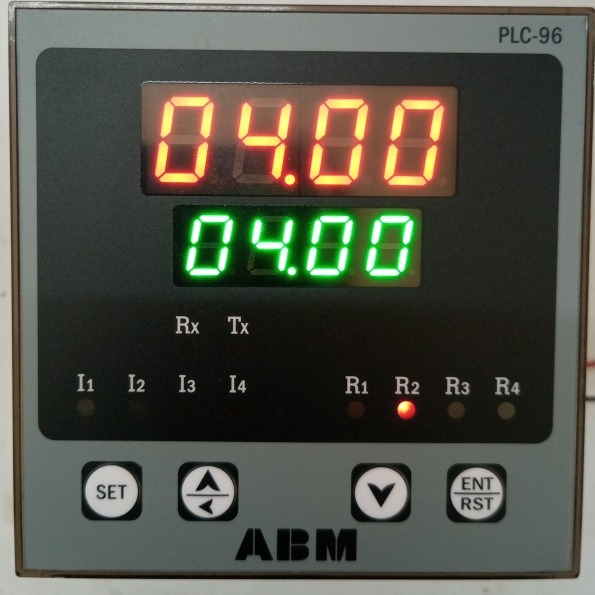

- PROCESS CONTROLLER (2RELAY)

- DIMENSION (96H×96W×75D) mm : PLC-96

ABM - INSTRUMENT

ABM - INSTRUMENT

A Process controller PLC96 is a programmable logic controller (PLC) manufactured by Silga Micro System. It is a programmable device that automates and controls industrial machinery and processes.

Features and specifications

- Application: The SMS-PLC-96 is intended for industrial use.

- Interface: It features a keypad for settings and configuration and an LCD display for monitoring.

- Dimensions: The physical size is 96 x 96 x 75mm with a panel mount cutout of 92 x 92mm.

- Power: The controller operates on a 24V DC supply voltage, though some models may vary.

- Inputs and Outputs: Standard models can include up to 4 digital inputs and 4 relay outputs.

- Customization: The manufacturer highlights that the PLC is customizable to meet the unique requirements of a specific industrial process.

Typical function

A PLC such as the

SMS-PLC-96

is used to replace hard-wired relay logic systems, offering improved reliability, flexibility, and ease of programming. It works by performing a continuous scan cycle:

- Input Scan: Reads the state of sensors and other input devices.

- Logic Execution: Executes the control program based on the collected input data.

- Output Update: Sends signals to control output devices like motors and valves according to the program logic.Customizable options

One of the primary benefits of theSMS-PLC-96is its customization. Depending on the application, Silga Micro System can modify the device to include:

Tailored solutions: Customized programming to match the unique requirements of a specific industrial process.

- Expanded I/O: The ability to handle more than the standard number of inputs and outputs.

- Integration: Can be built to seamlessly integrate with existing equipment and control systems.

- Application-specific variants: The manufacturer offers various custom versions for specialized tasks, such as:

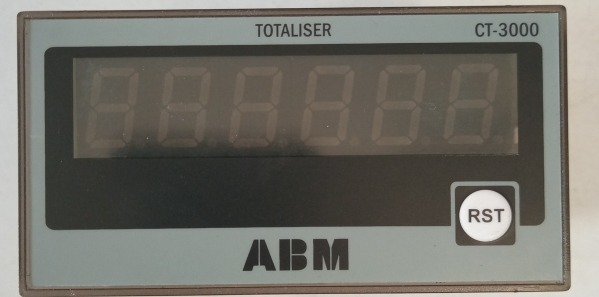

- Length counter: Can be configured for flowrate monitoring and counting operations, compatible with sensors like proximity switches and encoders.

- Asphalt plant controller (SMS-BS-96): A specialized variant for bitumen spray systems that controls temperature and flowrate.

- Weighing controller (SMS-WC-96): Features loadcell inputs and communication ports for integration into larger networks.

Typical industrial applicationsThe SMS-PLC-96 is used across various machine industries and industrial applications.- Road construction: In bitumen spray systems.

- Manufacturing: For the automation and control of general machinery.

- Industrial processes: For any process that requires precise control based on digital inputs, such as material handling and batching.

SUPPLIERS:–

The reliable manufacturers and suppliers of based in India.

Customers from all across India are placing repeated orders, as there is no alternative available in terms of quality and performance.

Premium quality raw materials are used in the manufacturing that ensures noteworthy features such as high durability and resistance to abrasion.

How to contact us

If you’ve got questions or ideas you would like to share, send a message. For anything more specific, please use one of the addresses listed below.

Our Location :

Westside Controls 7.B.Murli Vihar Behind Canara Bank Sarojini Nagar Lucknow 226008

Factory Westside Controls

Khasra no-174, Amausi Station Road Naderganj Industrial Area Lucknow226008

Direct Line Numbers

9776806777 , 0522-3642558

![Current Controller- [ABM]](https://factoryinputs.in/wp-content/uploads/2025/10/IMG-20251015-WA0004-430x430.jpg)

![Digital Presetable Counter - [ABM]](https://factoryinputs.in/wp-content/uploads/2025/10/106974tws-1400f-regular-430x430.jpg)

Reviews

There are no reviews yet.