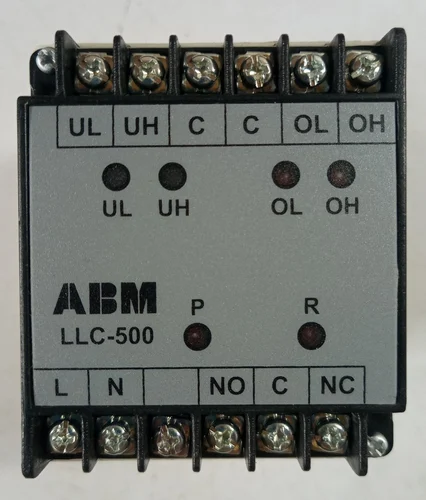

- LIQUID LEVEL CONTROLLER

- LLC-500

ABM - INSTRUMENT

ABM - INSTRUMENT

A liquid level controller is a device that monitors and regulates the level of liquid in a tank, vessel, or process. It works with a sensor to detect the liquid level and activates or deactivates a connected mechanism, such as a pump or valve, to maintain the liquid within a set range.

Common applications include controlling water levels in overhead tanks, regulating liquid levels in industrial process systems, and managing sump pumps in commercial and residential buildings.

Types of liquid level controllers

Liquid level controllers can be broadly categorized by their sensing technology:

Contact-based controllers

These sensors make direct contact with the liquid to determine its level.

- Float switch: Uses a buoyant floating device that rises and falls with the liquid level.

- How it works: When the liquid level reaches a certain point, the float's movement triggers a mechanical or electrical switch inside, which sends a signal to start or stop a pump.

- Best for: Simple, cost-effective on/off control in water tanks, sumps, and reservoirs.

- Example product: The

uses a float mechanism to automatically turn a motor on when the water is low and off when the tank is full.

- Conductivity probes: These use electrodes or probes that sense the liquid's conductivity to detect its level.

- How it works: An electrical current flows between the probes once they are submerged in a conductive liquid. The controller detects this change in resistance and activates a relay to control a pump or other device.

- Best for: Conductive liquids like water in a controlled, non-volatile environment. They can also be used for multi-point level detection.The term LLC 500 refers to two different types of products, depending on the manufacturer and context:

- A specific model of a domestic/industrial liquid level controller, typically for water pumps.

- A model in the Optomax series of industrial liquid level switches manufactured by SST Sensing.

Here are the details for each:1. LLC 500 Liquid Level Controller (Water Level Management)This is a general term or model name used by several manufacturers in India (e.g., by suppliers listed on ) for devices that automate water pumping operations in homes and industries.Key Features:- Function: Fully automatic operation to control water flow between underground and overhead tanks.

- Operation: Automatically switches the motor ON when the water level is low and OFF when the tank is full, preventing overflow and dry running.

- Sensors: Typically uses conductive stainless steel (SS) sensors placed at different levels in the tanks.

- Voltage: Often designed for single-phase (230V AC) or three-phase (415V AC) power supplies.

- Protection: Includes features like dry-run protection and LED indicators for water levels and motor status.

- Applications: Used in residential buildings, hotels, industrial complexes, and municipal water stations.

2. LLC500 Series Level Switch (Industrial Sensor)The LLC500 series from SST Sensing (part of the Optomax range) are optical liquid level switches used in a wide range of industrial sensing applications.Key Features:- Technology: These are optical sensors (not float-based) and are a type of point level switch.

- Operation: They provide a digital output (push-pull) that changes state when the liquid is detected or not detected at the sensor's point.

- Voltage: Operates on a low DC voltage range (typically 4.5V to 15.4V).

- Material: The housing and prism are often made of polysulfone (PES), making them suitable for various chemical compatibility requirements.

- Applications: Used in industrial settings where a reliable point-level detection is needed and non-contact sensing is preferred

SUPPLIERS:–

The reliable manufacturers and suppliers of based in India.

Customers from all across India are placing repeated orders, as there is no alternative available in terms of quality and performance.

Premium quality raw materials are used in the manufacturing that ensures noteworthy features such as high durability and resistance to abrasion.

How to contact us

If you’ve got questions or ideas you would like to share, send a message. For anything more specific, please use one of the addresses listed below.

Our Location :

Westside Controls 7.B.Murli Vihar Behind Canara Bank Sarojini Nagar Lucknow 226008

Factory Westside Controls

Khasra no-174, Amausi Station Road Naderganj Industrial Area Lucknow226008

Direct Line Numbers

9776806777 , 0522-3642558

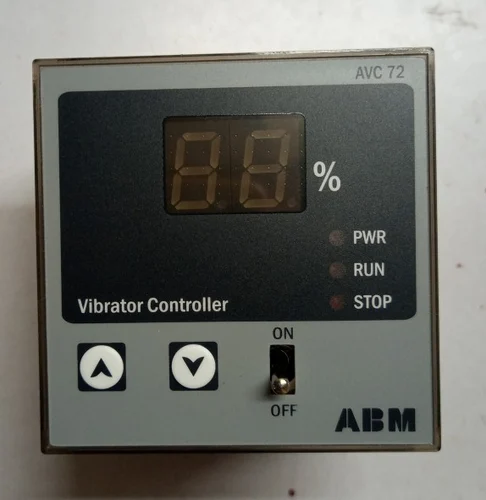

![SPECIAL PROCESS INDICATOR - [ABM]](https://factoryinputs.in/wp-content/uploads/2025/11/product-jpeg-1000x1000-1-1-430x430.webp)

![DIGITAL PROCESS INDICATOR - [ABM]](https://factoryinputs.in/wp-content/uploads/2025/11/product-jpeg-1000x1000-2-430x430.webp)

Reviews

There are no reviews yet.