- LAUNDRY TIMER

ABM - INSTRUMENT

ABM - INSTRUMENT

A forward reverse timer is a control device used in industrial automation systems to automatically switch the direction of a motor's rotation, typically with a safety pause in between directional changes.

Key Functions

- Directional Control: It operates control elements (usually contactors) to make a motor run in a forward or reverse direction.

- Time-Based Sequencing: Users can set specific time durations for how long the motor runs in the forward direction and how long in the reverse direction.

- Safety Interlock/Pause: A crucial feature is a built-in delay or pause time between the forward and reverse operations. This ensures the motor comes to a complete stop before attempting to reverse, which prevents damage from high current draw and mechanical stress.

- Automation: It eliminates the need for manual intervention in repeatedly changing the motor's direction, thereby improving efficiency and process control.

How It Works (General Principle)

The timer is part of a control circuit that typically includes contactors, relays, and start/stop switches.

- Start: When the start button is pressed, the forward contactor coil is energized, and the motor begins rotating in the forward direction. The timer is also activated.

- Forward Time Ends: After the preset forward time elapses, the timer's internal relay contacts change state. This action cuts the power to the forward contactor coil.

- Pause (Optional but Recommended): Many timers include an adjustable pause time feature. During this delay, neither the forward nor the reverse contactor is energized, allowing the motor to decelerate to a stop.

- Reverse Cycle Starts: Once the pause time is complete (or immediately after the forward time ends in simpler models), the timer energizes the reverse contactor coil. The motor then starts rotating in the reverse direction.

- Cycle Continues/Stops: This process can continue in a cyclic manner until a stop button is pressed or can be configured for single-cycle operations.

Common Applications

Forward reverse timers are widely used in industrial and commercial automation systems:

- Conveyor Belts: To move materials back and forth.

- Machine Tools: For specific operations requiring directional changes.

- Automated Gates/Doors: For opening and closing cycles.

- Mixing Processes: In chemical or pharmaceutical industries, where mixing in both directions may be required for specific durations.

The

FRT 1044

is a specific model of a digital, programmable forward-reverse timer manufactured by companies like Multispan, primarily designed for industrial automation and laundry machine applications.

Key Specifications and Features

- Model Number: FRT-1044 (sometimes referred to as FRT-1044N).

- Application: Predominantly used for laundry machines to control washing cycles, as well as general industrial automation where forward and reverse motor operation is needed.

- Display: Features a dual 4-digit, 7-segment LED display (upper red for current time, lower green for set time).

- Dimensions: The standard dimension is 96mm x 96mm x 50mm (HxWxD), with a panel cutout of 92mm x 92mm for flush mounting.

- Set Points: It typically has 4 set points that can be configured: Forward time, Stop time (pause), Reverse time, and an optional Total time.

- Operating Mode: The primary function is the specialized "Laundry Function" mode, which automatically sequences the motor through the forward, stop, and reverse cycles.

- Output: Equipped with two relays (1 C/O, 5A, 230V AC rating) to control the forward and reverse contactors.

- Time Range: The time setting range is highly configurable, typically in seconds, minutes, or a combination (e.g., 99.99/999.9/9999 Sec/Min).

- Input: Can accept input start pulses from a proximity switch, micro switch, or limit switch.

- Reset: The timer can be reset from the front keypad and/or a remote input.

- Power Supply: Operates on a single-phase 230V AC supply (range generally 100-270V AC).

Key Specifications and Features

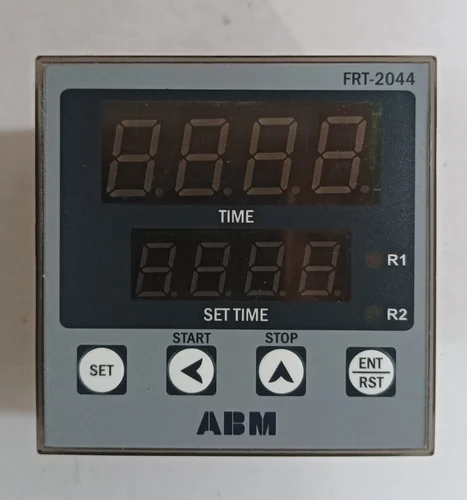

- Model Number: FRT-2044 (or UTR-2044 as a universal timer variant).

- Dimensions: The unit measures 72mm x 72mm x 85mm (HxWxD).

- Panel Cutout: It requires a panel cutout of 68mm x 68mm for mounting.

- Display: It features a dual 4-digit LED display (upper red for time value, lower green for set value).

- Applications: Commonly used in industrial processes, control panels, and automation systems requiring time-based operations like delayed ON/OFF, cyclic modes, or basic forward/reverse motor control.

- Output: Typically includes one or two relays (2 C/O contacts, 5A, 230V AC rating), depending on the specific configuration or mode selected.

SUPPLIERS:–

The reliable manufacturers and suppliers of based in India.

Customers from all across India are placing repeated orders, as there is no alternative available in terms of quality and performance.

Premium quality raw materials are used in the manufacturing that ensures noteworthy features such as high durability and resistance to abrasion.

How to contact us

If you’ve got questions or ideas you would like to share, send a message. For anything more specific, please use one of the addresses listed below.

Our Location :

Westside Controls 7.B.Murli Vihar Behind Canara Bank Sarojini Nagar Lucknow 226008

Factory Westside Controls

Khasra no-174, Amausi Station Road Naderganj Industrial Area Lucknow226008

Direct Line Numbers

9776806777 , 0522-3642558

![DIGITAL PANEL METER - [ABM]](https://factoryinputs.in/wp-content/uploads/2025/11/IMG-20251015-WA0017-430x430.jpg)

![PROCESS INDICATOR - [ABM]](https://factoryinputs.in/wp-content/uploads/2025/11/product-jpeg-1000x1000-4-430x430.webp)

Reviews

There are no reviews yet.