- BATCH COUNTER - BC

A batch counter is an electronic device that counts individual items and organizes them into predetermined groups or "batches". It is commonly used in industrial and production settings to automate tasks like packaging, improve accuracy, and control quality by signaling a machine to stop or perform an action once a specific number of items is reached. These counters often work with sensors, like proximity sensors or micro switches, which detect the items and send a signal to the counter to increment the count.

- Counting and grouping: Counts individual items and triggers an action, such as stopping a machine, after a set quantity is counted.

- Programmable presets: Allows users to set the desired number of items in a batch.

- Totalizer function: Many models also include a totalizer, which keeps a running count of all items processed, even after a batch is completed and reset.

- Sensor input: Receives input from sensors like proximity sensors (PNP/NPN) or micro switches to detect items.

- Output: Can control an output, such as activating a relay, to signal a connected device or machine.

- Resettable: Can be manually or automatically reset to begin counting a new batch.

- Display: Typically features a digital display (like LED or LCD) to show the current batch count, total count, and settings.

- Common applications

- Packaging:

Counting items like papers, pills, or components to package them into specific quantities.

- Production lines:

Stopping a conveyor belt or machine after a certain number of products have passed.

- Counting and sorting:Used in logistics and other industries to count and sort items as they move through a process.

- Types of Batch CountersBatch counters can be categorized by their mechanism and features:

- Mechanical Batch Counters: These are traditional, durable devices using physical mechanisms (gears, levers) to count. They are reliable in harsh conditions but lack advanced features and automation capabilities.

- Electronic/Digital Batch Counters: The most common modern type, using electronic circuits and digital displays. They offer high precision, programmable settings, and are widely used in pharmaceuticals, packaging, and automotive manufacturing.

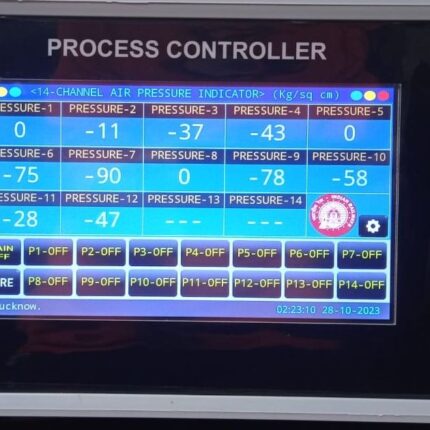

- Pneumatic Batch Counters: Designed for systems involving air pressure, using pneumatic sensors to detect items. They are common in certain food and beverage industry applications where pneumatic conveyors are used.

- Programmable Logic Controllers (PLCs): In complex industrial settings, the batch counting function is often integrated into a PLC, which provides a high degree of control and flexibility, allowing for integration with other systems in a production line.

- Machine Vision Systems: For high-speed or complex counting scenarios, vision systems use cameras and AI to count items, reject out-of-tolerance parts, and provide high accuracy.

SUPPLIERS:–

The reliable manufacturers and suppliers of based in India.

Customers from all across India are placing repeated orders, as there is no alternative available in terms of quality and performance.

Premium quality raw materials are used in the manufacturing that ensures noteworthy features such as high durability and resistance to abrasion.

How to contact us

If you’ve got questions or ideas you would like to share, send a message. For anything more specific, please use one of the addresses listed below.

Our Location :

Westside Controls 7.B.Murli Vihar Behind Canara Bank Sarojini Nagar Lucknow 226008

Factory Westside Controls

Khasra no-174, Amausi Station Road Naderganj Industrial Area Lucknow226008

Direct Line Numbers

9776806777 , 0522-3642558

![Protection Device - [ABM]](https://factoryinputs.in/wp-content/uploads/2025/10/mpd-96-three-phase-protection-device-500x500-1-354x430.webp)

![DIGITAL LENGTH COUNTER - [ABM]](https://factoryinputs.in/wp-content/uploads/2025/11/32437lc-2046-regular-430x430.jpg)

Reviews

There are no reviews yet.